Teensy 3.1 based reflow oven Controller with TFT 2.8″ touch – on screen control.

Teensy 3.1 takes care of the usual tasks of a reflow controller, namely running the PID loop needed to accurately control the oven’s temperature and control the heating profile.

This Reflow Oven Controller controls your reflow oven using the attached K type temperature sensor which is located in the oven – on top of baking PCB(s).

Adjustable is Conformance to specific time and temperature profiles, necessary in order to obtain the best results for reflow, when soldering SMD components with solder paste.

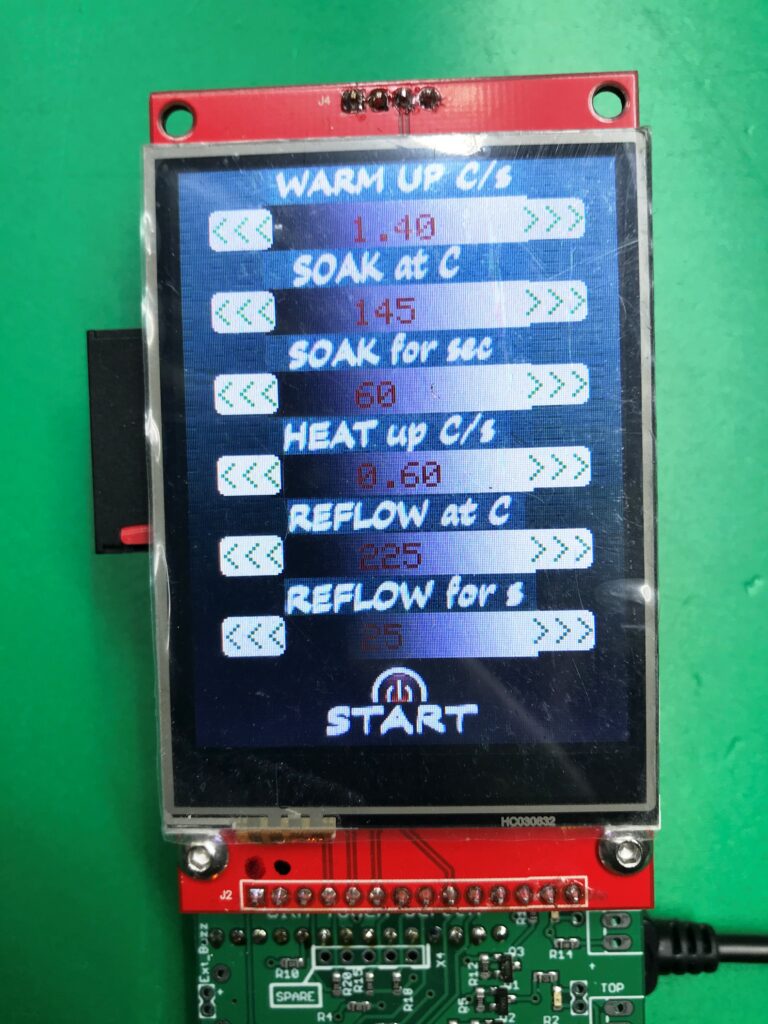

- To configure the controller parameters, you need to set apropriate Profile on TFT screen. Actual reflow profile graph is presented on the screen, and in addition you can monitor actual temperature by serial interface port on your PC when needed.

- Boards and components are heated gradually during the preheating phase. This avoids generating mechanical stresses in the board and the components.

- After preheating, the temperature is briefly raised to just below the soldering temperature. This allows the volatile ingredients of the solder paste to escape without forming bubbles.

- Than, the temperature is raised to the soldering temperature.

- The solder paste liquefies and bonds the components to the board. The soldering temperature is maintained precisely during the soldering time to prevent damage from overheating.

- The controller emits an acoustic signal to mark the end of the soldering phase, you need to open the front door for cooling to start take effect.

- After cooling is done, the fully soldered boards can be removed from the oven.

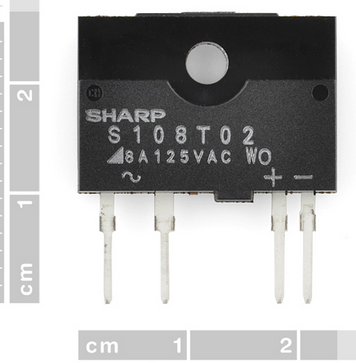

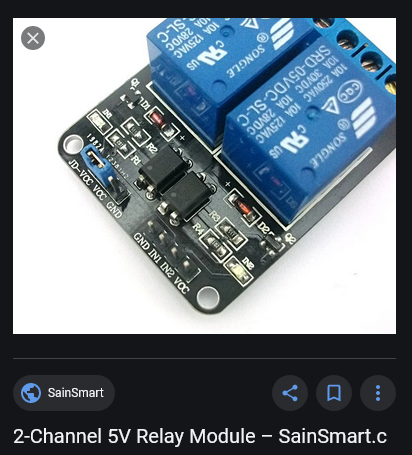

Needed Parts for installation into the Oven:

Typical RoHS profile