DISPENSER for Manual solder Paste

application to PCB for reflow soldering or Hot-Air Soldering technics

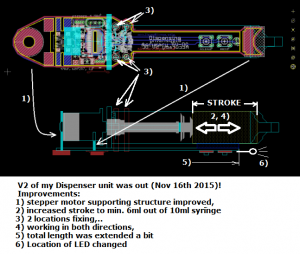

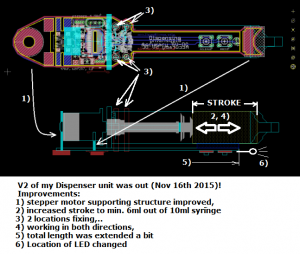

Electronic 5V DC powered Solder paste V2 Dispenser AIR FREE /AIR LESS operation. V2 and V3

The goal to build this Dispenser was to be as cheep as possible and to avoid using any 3D printed parts! But still reliable and safe for use by hobby guys and school kids for low volume of PCBs.

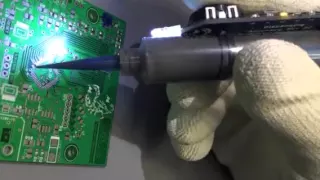

This solder paste dispenser is generally to be used with any solder paste in a syringe (or flux, liquid, glue,..) – syringe volume 10 to 15 cc.

Two buttons for PRESS and RELEASE turn the stepper motor shaft left or right and move piston in syringe in chosen direction and force the liquid or paste in syringe to move out through needle.

Dispenser has built in very powerful stepper motor with full metal gear gearbox witch with tremendous pressure forces paste or liquid out of the syringe. Basic use is for SMD SMT solder paste application to PCB for reflow soldering.

Appx. 25x PRESS-ings make 1 (one) rotation of the piston which moves the piston for apx. 0.5-1mm (0,019685 -0,3494 dec. inch) in the syringe.

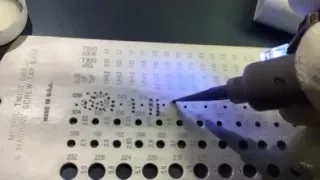

I tested this V1 and V2 of Dispenser with several different Solder Paste Manufacturers and different needle sizes:

1) Blue/metric 0,41mm – US/Gauge 22- https://www.youtube.com/watch?v=uP4FD3tp3ck

2) Purple Gage 21 – 0.51mm

https://www.youtube.com/watch?v=LzHhUJj54ug

3) Gauge 23-24 (inside Dia 0.38 -0.41 mm)

https://www.youtube.com/watch?v=o4PbVOhY2UQ

and as well stepper motor force produced – apx. 14 kg / 30 pounds

https://www.youtube.com/watch?v=pAvSR6YC-Bs

Power Supply needed is 5V DC (0.5 to 1A). I simply use USB cable and phone charger or computer USB port, spare phone USB battery pack…or similar.

Due to fact that many Solder Paste Co. request in manuals storage of the Solder Paste in cool areas with 0-10deg C storage temperature please note that Syringes stored in fridge shall be heated up with hot air/ shrink tube hot air gun / hair drier or in hot water to 40-60 deg C for better viscosity of solder paste for use with this dispenser.

You have to take into account that this Dispenser is not as fast as air dispenser but it is fast enough to keep you doing right thing! I have placed a few videos on my You Tube – test with different needles and paste,… have a look!!

Here is a procedure we worked-out with one of my German Client: I quote the email text:

“I didn’t pre-heat the solder paste, just took it out of the fridge and let it rest for some hours at room temperature. I built up pressure until some paste came out of the needle and then released the pressure. First I tried pressing and instantly releasing again, but it was quite hard to get the right amount of paste on the pads…. It was a success with pressing and not releasing after. While the paste was slowly flowing I just did pad after pad and always got the right amount. I tried different needles and it worked even with really narrow ones. Did some DFNs, TQFPs, SSOPs, and many 0603s. Worked really neat, just had to remind me to build new pressure once in a while 🙂

I like the dispenser and I’m happy to finally leave my toothpick method behind me 🙂 “”

Best regards,

Nicolas

I would highly recommend BEGINERS NOT TO start with metal needles but with but with PLASTIC CONICAL outlets!!

Reference:

please refer to:

– http://wordpress.mencinger.biz/

– See photos here attached and in the blog at

http://www.eevblog.com/forum/reviews/solder-pasteflux-manual-syringe-applicator/

-My You Tube video link: https://www.youtube.com/watch?v=QcRrEAo1YXs

M.Mencinger, December 2015

Package Included:

1x PCB with Stepper Motor and build inn parts as on photo. (blue PCB & transparent cover),

1x Syrinage 10ml with LOCK needle output neck,

9 pcs plastic needles as on photo,

4 pcs cable ties,

NOT in supply 5V DC Charger and USB cable.

Do not hesitate to ask questions!!

GERMAN TEXT:

Lotpaste Spender/(Dispenser) – Controller – Extruder

Platine fertig montiert und geprüft.

Preis gilt für einen Lotpaste Spender, montiert und getestet. – siehe Foto.

Zentrale Funktionen:

Der Lotpaste Spender ist für Spritzen mit Lotpaste (Spritzen Volumen von 10

bis 15cc) .

Im Kühlschrank gelagert Spritzen sollten vor der Verwendung in heißem

Wasser auf 40 bis 60 °C aufgeheizt werden.

Funktionsweise:

Zwei Tasten, kurzer druck (Motor links + rechts)

Ca. 25 mal Drücken ergibt eine (1) Umdrehung des Kolbens, was einer Strecke von

etwa 0,5 mm entspricht.

Sehr leistungsstarker Shrit Motor mit starkem Druck für Reflow-Löten mit SMD/ SMT

Lotpaste auf Leiterplatten geeignet.

Stromversorgung und USB-Kabel erforderlich (beides nicht im Angebot

enthalten): 5V DC – 1A -siehe Bilder.

You Tube video link: https://www.youtube.com/watch?v=QcRrEAo1YXs

http://www.eevblog.com/forum/reviews/diy-solder-paste-dispenser/15/

more here : http://www.eevblog.com/forum/reviews/solder-pasteflux-manual-syringe-applicator/90/ with some videos…

Lieferinhalt:

1x PCB mit Motor Kolben und bauen inn Teile. (blaue PCB & transparente Abdeckung).

1x Syrinage 10ml with LOCK needle output neck,

9 pcs plastic needles as on photo,

4 pcs cable ties,

NICHT in Versorgung: 5V DC-Ladegerät und USB-Kabel.

Zögern Sie nicht Fragen zu stellen !!

MD Lötpaste Spender V3- Controller / Extruder-Platine mit montierten und geprüften Teilen.

Der Preis ist für 1einen Spender mit bestückter & getesteter Platine. ( siehe Foto.)

Zentrale Funktionen:

Der Lötpaste Spender ist verwendbar auch für Flussmittel, etc. (Spritzenvolumen 5-10, 15 ml max.), über den Joystick wird der Schrittmotor gesteuert der den Kolben nach vor oder zurück bewegt.

Die Stepper Geschwindigkeit und somit auch die Kolben Geschwindigkeit wird, entweder über den Joystick oder den eigenen „Speed Button“ gesteuert.

Es gibt 5 Geschwindigkeiten die über die 5 onboard LED’s angezeigt werden, in der Höchsten Geschwindigkeit wird der Kolben um ca. 0,5-1mm in die Spritze reinbewegt.

Der sehr leistungsfähige Schrittmotor mit Vollmetallgetriebe erzeugt einen hohen Druck ist ideal für SMD SMT Lotpaste Anwendung für Reflow-Löten.

Ein externes 5V 1A Netzteil mit Mini USB Stecker ist erforderlich (ist in den Preis nicht inkludiert) , siehe Foto.

Detailfotos und weitere Informationen sind unter folgenden Links zu erreichen:

http://www.eevblog.com/forum/reviews/solder-pasteflux-manual-syringe-applicator/240/

Dispnser for solder paste, glue, liquid … V6 ;

Spritzen die im Kühlschrank aufbewahrt werden, müssen vorher mit Heißluft / Fön oder in heißem Wasser bei 40-60°C erwärmt werden um eine bessere Viskosität der Lötpaste zu erreichen.

You-Tube Video-Link: https://www.youtube.com/watch?v=ucoj6OZu5kI

Lieferinhalt: